ROLLING PROCESS

Process control

- Optimal rolling schedules

- Profile and flatness

- Interstand cooling

- Laminar cooling

Process simulation & optimization

Rolls

- Sleeved rolls

- Optimal grinding of rolls

- Optimization of BuR grinding & performance

- CoolRoll software

- Section cooling

Know-how

Optimal rolling schedules

Rolling schedule is the time sequence of passes of rolled piece through the mill respecting many constrains and limitations as:

- limit separating force,

- rolling torque,

- bite angle,

- flatness limits,

- metallurgical limits,

- specific limits (length of delay table, coiling thickness etc).

If all constrains are fulfilled, rolling schedule gives maximum productivity (minimum production time) and the strip/sheet is flat with required profile, we can speak about optimum rolling schedule.

The OPP Software serves for automatic calculation of optimum rolling schedules on reversing mills. It is based on optimization methods coupled with many other physical models. The OPP Software enables pass scheduling for strips/sheets made of various materials and rolled under various hot or cold conditions.

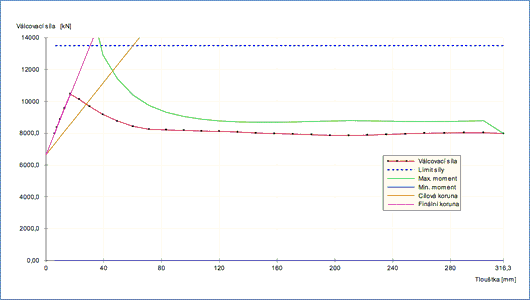

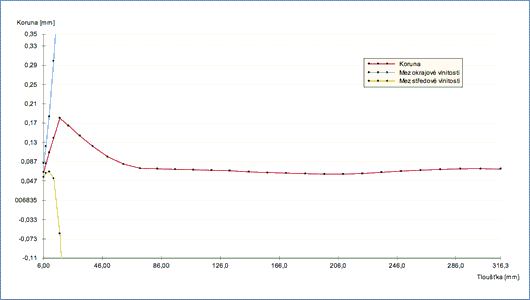

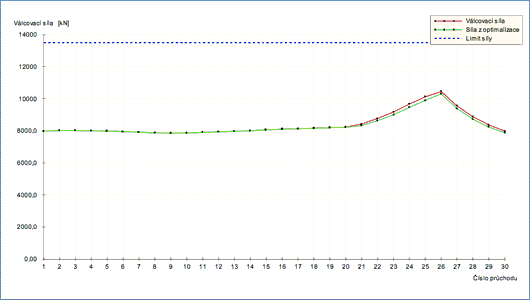

There is the pass schedule showed below as an example of hot rolling of AlMg3 alloy strip designed by the OPP Software.

The input parameters are dimensions and initial temperature of slab, material grade, target dimensions of the strip and target crown (profile).

Result of OPP calculation is optimum rolling schedule ensuring flatness, gives target crown, gives the shortest production time and respects all limiting mill criteria.

References:

Optimal pass schedules for the HSM (U. S. Steel Košice, Slovak Republic)

Rolling schedules with regard to strip flatness for Al-alloys (Al Invest Břidličná, Czech Republic)

Optimization of pass schedules on the HSM Twin Steckel (LIBERTY Ostrava, Czech Republic

Optimal pass schedules for Al-alloys rolling on Duo 800 stand (COMTES FHT, Czech Republic)