ROLLING PROCESS

Process control

Process simulation & optimization

Rolls

- Sleeved rolls

- Optimal grinding of rolls

- Optimization of BuR grinding & performance

- CoolRoll software

- Section cooling

Know-how

Optimal grinding of rolls

Through the work and backup rolls grinding proper option the strip flatness can be influenced and rolls wear in the contact diminished.

Roll Grinding Effect on Strip Flatness

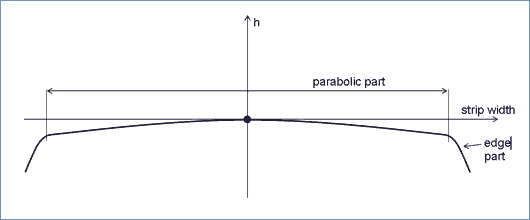

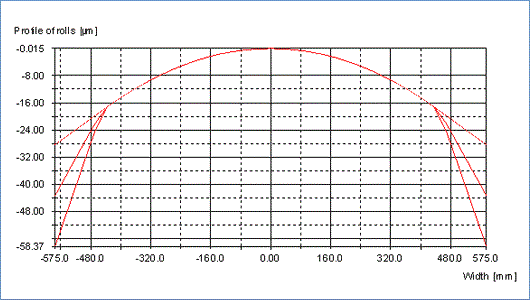

Through the work and backup rolls proper grinding the strip flatness can be achieved as well as bending forces extending in the allowed range during the whole work rolls campaign. While rolling a strip with a stable width (a situation usual at cold mills), through a special grinding it can be achieved still better flatness than on usual rolls with a parabolic profile.

Typical cold strip profile with an abrupt thickness reduction on its edges is presented on the following picture. This phenomenon implicates often occurence of edge waviness.

This feature can be prevented with a help of a special grinding shape – see the following figure:

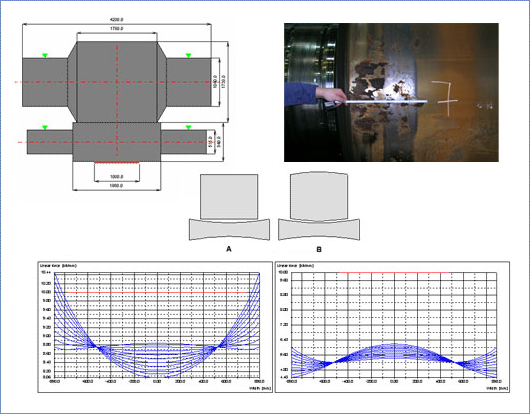

Rolls Grinding Effect on Their Wear and Failure

Through the work and backup rolls proper grinding it is possible to reach the reduction of the pressure between rolls and to eliminate the rolls failure danger as a final result.

References:

The analysis and optimization of grinding of sleeved rolls (Springfield Machine & Tool, Inc., Battle Creek, MI, USA, 2018)