ROLLING PROCESS

Process control

- Optimal rolling schedules

- Profile and flatness

- Interstand cooling

- Laminar cooling

Process simulation & optimization

Rolls

- Sleeved rolls

- Optimal grinding of rolls

- Optimization of BuR grinding & performance

- CoolRoll software

- Section cooling

Know-how

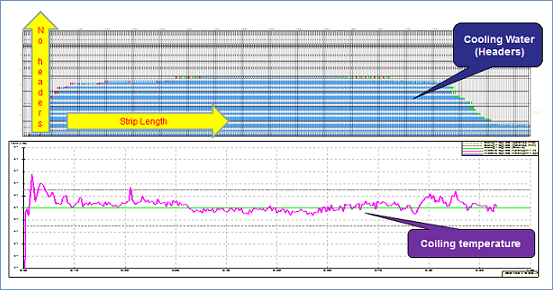

Laminar cooling

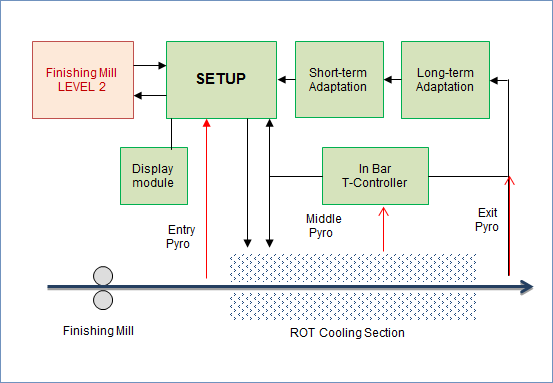

Control systems for HSM run out table cooling (Laminar Cooling) to reach the required coiling temperature.

The effects of laminar cooling:

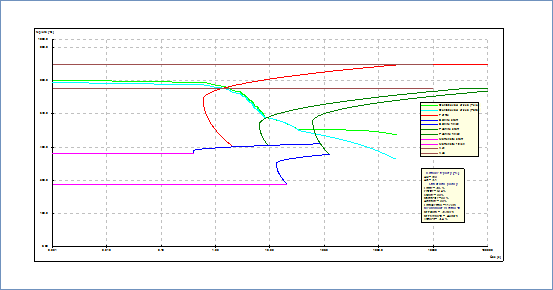

- Keeping of coiling temperatures ± 15 °C with differences of Exit Rolling Temperature 150 °C,

- Good agreement in predicted yield stress and tensile strength,

- Simulations – development of cooling technologies

- Extensive monitoring possibilities.

References:

Laminar cooling control system on HSM Twin Steckel (LIBERTY Ostrava, Czech Republic)