ROLLING PROCESS

Process control

- Optimal rolling schedules

- Profile and flatness

- Interstand cooling

- Laminar cooling

Process simulation & optimization

Rolls

- Sleeved rolls

- Optimal grinding of rolls

- Optimization of BuR grinding & performance

- CoolRoll software

- Section cooling

Know-how

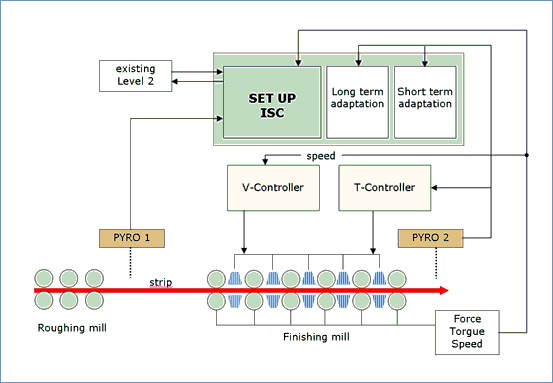

Interstand cooling

The Inter Stand Cooling (ISC) at strip hot strip mills partakes fundamentally in reaching and maintaining the required finishing rolling temperatures. Thus it enables to reach better mechanical properties of a strip, particularly with microalloyed steels. Very important is the possibility to increase the mill production so that it enables to roll at higher speed or speed up.

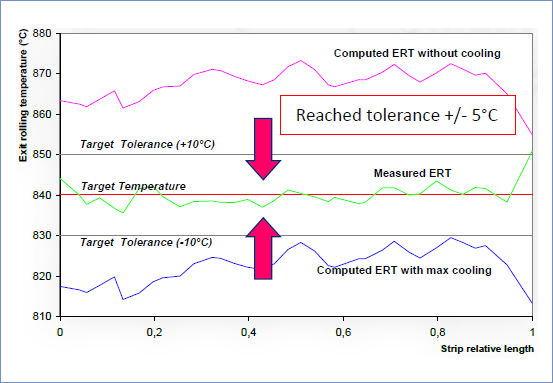

Effects of ISC cooling on hot strip mill 2000 m:

- thin strips (< 4 mm): deviation ± 7 °C

- thick strips (> 10 mm): deviation ± 12 °C

- increase of rooling speed: cca 30 %

References:

Implementation of new models for interstand cooling control system on hot strip mill, Level 2 (U. S. Steel Košice, Slovakia)

Interstand cooling control system on hot strip mill 2005 mm, Level 2 (ArcelorMittal South Africa, Vanderbijlpark, South Africa, 2010)

Interstand cooling control system on hot strip mill 2000 mm, Level 2 (OAO Severstal, Cherepovec, Russia, 2006)