ROLLING PROCESS

Process control

Process simulation & optimization

Rolls

- Sleeved rolls

- Optimal grinding of rolls

- Optimization of BuR grinding & performance

- CoolRoll software

- Section cooling

Know-how

CoolRoll SOFTWARE

Computer simulation of cooling of work rolls

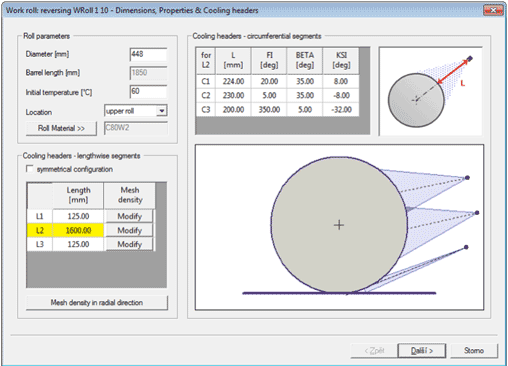

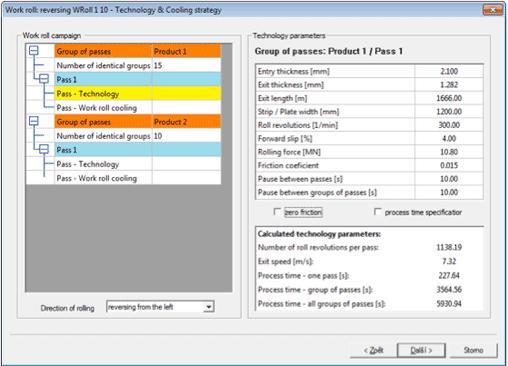

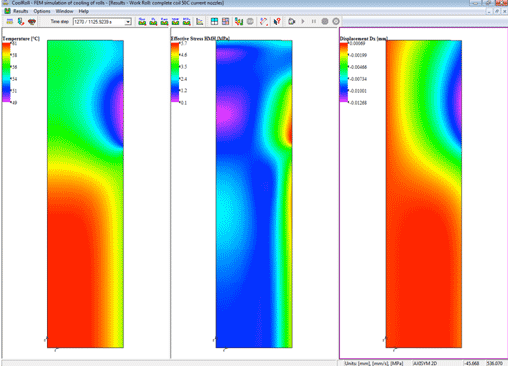

CoolRoll is a software designed for off-line computer simulation of temperature profile and thermal camber of flat work rolls during hot or cold rolling campaign. The software allows to study the effects of various distribution and intensity of cooling of nozzles in longitudinal and circumferential direction of the work roll on changes of its temperature and longitudinal profile. CoolRoll is based on the 2D FEM axisymmetric transient heat algorithm.

The CoolRoll Software enables:

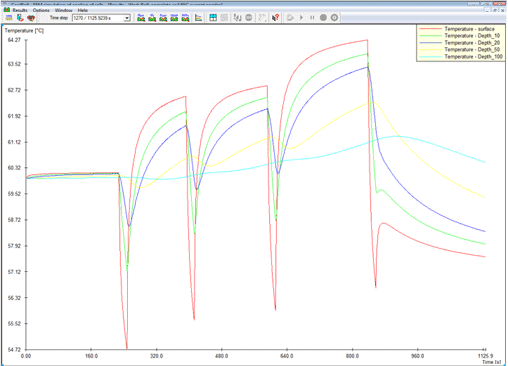

- to calculate work roll temperature profiles in specified time for various cooling strategies and various rolling campaigns,

- to study the time evolution of the longitudinal profile of the work roll due to changes of its temperature during the rolling (thermal camber, section cooling),

- to calculate thermal elastic stresses and strains.

The CoolRoll is equipped by friendly graphic user interface with fully automatic building of the FEM model:

The CoolRoll Software clearly displays the results of computer simulations:

References:

Spraying Systems Co., Wheaton, IL, USA

Spraying Systems do Brasil, Sao Paulo, Brazil

CSN, Volta Redonda, Rio de Janeiro, Brazil

Hyundai Steel, South Korea