ROLLING PROCESS

Process control

Process simulation & optimization

Rolls

- Sleeved rolls

- Optimal grinding of rolls

- Optimization of BuR grinding & performance

- CoolRoll software

- Section cooling

Know-how

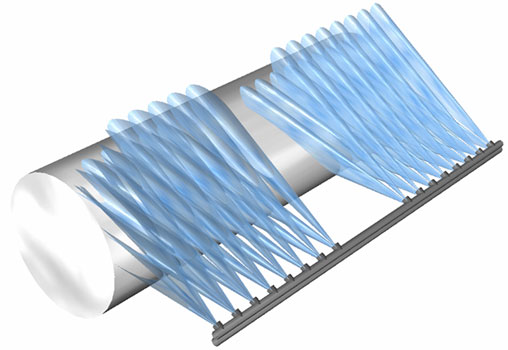

Section cooling

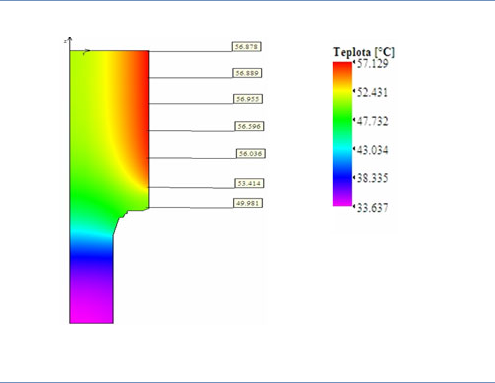

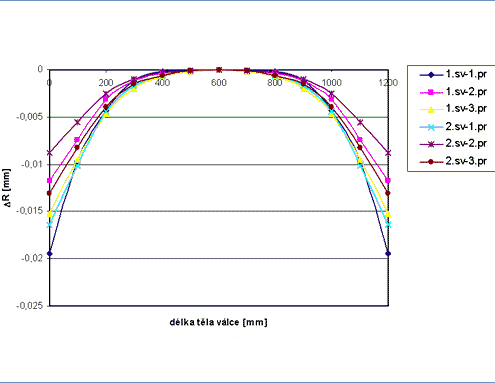

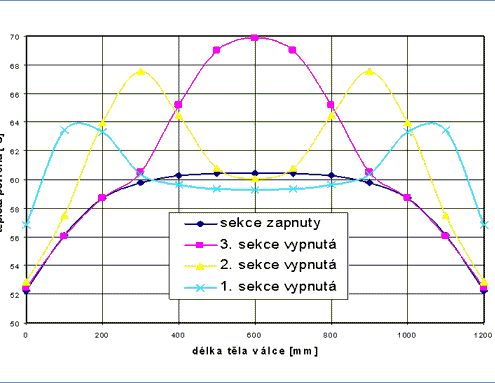

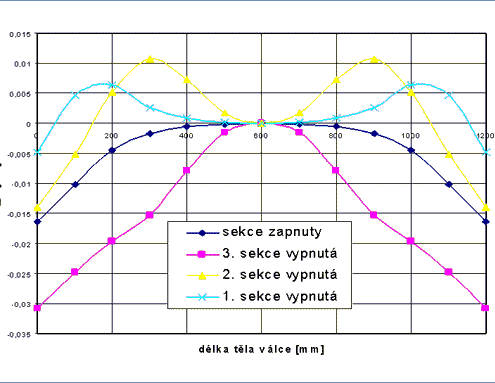

The section cooling primary function is to ensure that the work roll surface is not overheated. Moreover, owing to different cooling conditions in individual sections it is possible to affect the rolled material’s cross section and thus to help maintaining the rolled strip flatness.

References:

Computation of work roll shape on the 4h-stand for different conditions of section cooling (GO Steel, Frýdek-Místek, Czechia)

Cooling of work rolls in CSN Paraná (Spraying Systems do Brasil, Sao Paulo, Brazil)

Cooling of work rolls in CSN Volta Redonda (Acos Villares, Sao Paulo, Brazil)

Design of the work rolls cooling system on cold strip mill (CSN, Volta Redonda, Rio de Janeiro, Brazil)

Computational modeling of 4-high stand work roll shape for different section cooling conditions during cold strip rolling (GO Steel a. s., Frýdek-Místek, CZ)

The CoolRoll Sofware is a tool designed for off-line computer simulation of temperature profile and thermal camber of flat work rolls during hot or cold rolling campaign: